Single Blog

- Home

- Blog

- Automotive

- What are functional domains in automotive and their different types?

Overview

So, hello guys, and welcome back to the Gettobyte Automotive Technology series of blogs. In today’s blog, we are going to dig into different electrical/electronic sub-systems used in Automotive.

The automotive industry is today the sixth largest economy in the world, producing around 70 million cars every year and making an important contribution to government revenues all around the world.

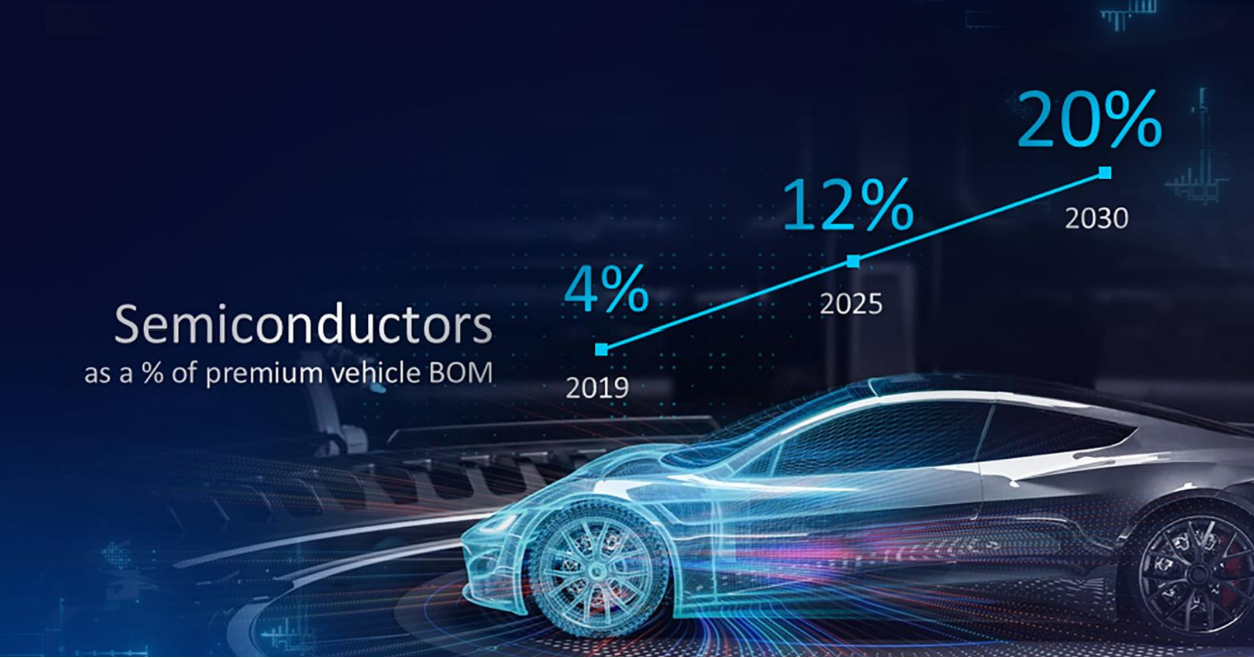

Automotive Vehicles are no longer mechanical systems, they are one of the largest consumers of Semiconductor chips like microcontrollers, microprocessors, ASIC’s, Integrated Circuits, embedded hardware, and Software solution around these semiconductor chips.

Infact at a time in a modern automotive vehicle there are more than 1000’s of Integrated Circuits and more then 1 lakh lines of code running in vehicles. Indeed, since then, the sector of embedded electronics, and more precisely embedded software, has been increasing at an annual rate of 10% in automotive industry.

Electronic technology has made great strides and nowadays the quality of electronic components—performance, robustness, and reliability—enables use of them even for critical systems. At the same time, the decreasing cost of electronic technology allows them to be used to support any function in a car. Furthermore, in the last decade, several automotive-embedded networks such as local interconnect networks (LIN), Controlled Area Network (CAN), TTP (Time-Triggered Protocol), FlexRay and Ethernet were developed.

Multimedia and telematic applications in cars are increasing rapidly due to consumer pressure; a vehicle currently includes electronic equipment like hand-free phones, audio/radio devices, and navigation systems. For the passengers, a lot of entertainment devices, such as video equipment and communication with the outside world are also available. These kinds of applications have little to do with the vehicle’s operation itself; nevertheless, they increase significantly as part of the software included in a car.

Examples of these facts:

- In 2004, the embedded electronic system of a Volkswagen Phaeton was composed of more than 10,000 electrical devices, 61 microprocessors, 3 controller area networks (CAN) that support the exchanges of 2500 pieces of data, several subnetworks, and one multimedia bus.

In the Volvo S, inter-car network support the communication between the microprocessors controlling the mirrors and controlling the doors, for example, the position of the mirrors is automatically controlled according to the sense of the near-by vehicle and the volume of the radio is adjusted to the vehicle speed, information provided, by the antilock braking system (ABS) controller.

- In a recent Cadillac, when an accident causes an airbag to inflate, its microcontroller emits a signal to the embedded global positioning system (GPS) receiver that then communicates with the cell phone, making it possible to give the vehicle’s position to the rescue service.

These are just a few examples, but there are many more that could illustrate this very large growth of embedded electronic systems in modern vehicles. Now in This blog, we are going to dip deeper into these electronics sub-systems in an automotive vehicle.

What are functional domains in Automotive?

To get a hierarchical understanding of the electronics used in a car, one can divide the car into different parts. These parts are basically in the car termed as Domains.

According to the European ITEA EAST-EEA project, a domain is defined as, a sphere of knowledge, influence, and activity in which one or more systems are to be dealt with (e.g., are to be built). The term domain can be used to group mechanical and electronic systems. A vehicle domain describes the grouping of systems and functions in a vehicle that can be assigned to individual areas.

Historically, there are 5 domains in automotive:

From one domain to another, electronic systems often have very different features. For example, the powertrain and chassis domains both exhibit hard real-time constraints and a need for high computation power. The telematic domain presents requirements for high data throughput. However, the hardware architecture in the chassis domain is more widely distributed in the vehicle. From this standpoint, the technological solutions in each domain used are very different, for example, the communication networks, the design techniques, and the verification of the embedded software are different for each domain.

These 5 domains, cover all the electronic/electrical sub-systems of the car. You can think of any sub-system that you can think of, and it will fall in one of the above domains specified. Let’s just deep dive into each of these domains to understand which electrical sub-systems come in which domain.

Different types of functional domain in Automotive

To understand each of the domains, we will broadly be going to answer 3 questions:

- What parts of the vehicle fall into the corresponding domain?

- Examples of Automotive sub-systems for that corresponding domain.

- Sensors/Actuators/Modules used in that corresponding domain.

PowerTrain Domain:

This domain represents the system that controls the engine, such as:

A) According to requests from the driver:

→ Speeding Up and Slowing Down as transmitted by the throttle position sensor or brake pedal.

B) And from other parts of the embedded system such as:

→ Climate control (natural factors like air current temperature, oxygen level and environment annoyances such as exhaust pollution, noise and etc) and Electronic Stability Program (ESP): is a computerized technology that improves a vehicle’s stability by detecting and reducing loss of traction (skidding).

A) The quantity of fuel that has to be injected into each cylinder at each engine cycle according to the engine’s revolutions per minute (rpm) and the position of the gas pedal.

B) Ignition timing and Variable valve timing(VVT) control the time in the engine cycle at which the valves open.

C) Traction Inverters: Traction inverter is a power electronic device that converts the DC power from the battery into AC power to drive the electric motor in electric and hybrid vehicle.

There are others also like the optimal flow of air into the cylinder, exhaust emission, and the list goes on.

Sensors Used in Powertrain Domain

- A) Apart from the Engine, the powertrain domain takes into account the different working modes of the motor.

- B) Two major concerns for automotive engineers are how best to maximize fuel economy and to reduce emissions. Powertrain sensors, which measure temperature, pressure, rotational speed and other vehicle performance parameters, are central to both.

- iii) Some information, such as the current rpm, the vehicle speed, etc., are transmitted by this system to another one whose role is to present them to the driver on a dashboard; this last component is actually part of the HMI domain where these parameters are displayed.

- The Powertrain domain has: Continuous, sampled, and discrete systems are all found in this domain. Their specification and validation are supported by tools such as Matlab/Simulink. Their deployment and their implementation are the source of a lot of technical problems:

- Underlying control models are generally based on floating point values. If, for economical reasons, the implementation has to be done on a microcontroller without a floating point coprocessor, the programmer has to pay attention to the accuracy of the values to be sure to meet the precision required at the specification level of the control laws.

- A major challenge, as mentioned previously, is to efficiently schedule cyclic activities, because some of them have constant periods, while others have variable periods, according to the motorcycles. This means that scheduling them depends on different logical clocks.

- The power train domain is subject to hard real-time constraints, performance evaluation and timing analysis activities have to be performed on their implementation models first.

Chassis Domain :

This domain represents the system,

A) Whose aim is to control the interaction of the vehicle with the road (wheel, suspension, etc.)

B) and systems that take into account the requests emitted by the driver(steering, braking or speed up orders), the road profile and the environmental conditions, like wind.

- The chassis domain is of the utmost importance for the safety of the passengers and of the vehicle itself. Therefore, its development has to be of high quality, as for any critical system.

- Anti Braking System(ABS)

- Anti Lock Braking System: Diagram, Parts & Working [PDF] (theengineerspost.com)

- Electronic Stability Program(ESP)

- Electronic stability program (ESP®) (bosch-mobility.com)

- Automatic Stability control(ASC)

- Continental Automotive – Electronic Stability Control (ESC) (continental-automotive.com)

- How Electronic Stability Control Works | HowStuffWorks

- 4-wheel drive(4WD)

Sensors Used in Chassis Domain

For the powertrain domain, and the chassis domain, components are fully distributed onto a networked microcontroller and they communicate with each other systems.

- Electronic Stability Program(ESP): is part of the chassis domain that corrects the trajectory of the vehicle by controlling the braking system. Its role is to correct the trajectory of the vehicle as soon as there is understeering or oversteering. To do so, it has to compare the steering request of the driver to the vehicle response. This is done via several sensors distributed in the vehicle(lateral acceleration, rotation, individual wheel speeds) taking samples 25 timer per second. As soon as a correction needs to be applied, it will brake individual front or rear wheels and command a reduction of engineer power to the powertrain systems.

- X-by-wire: technology, currently applied in avionic systems, is emerging in automotive industry. X-by-wire is a generic term used when mechanical and/or hydraulic systems are replaced by electronic ones.

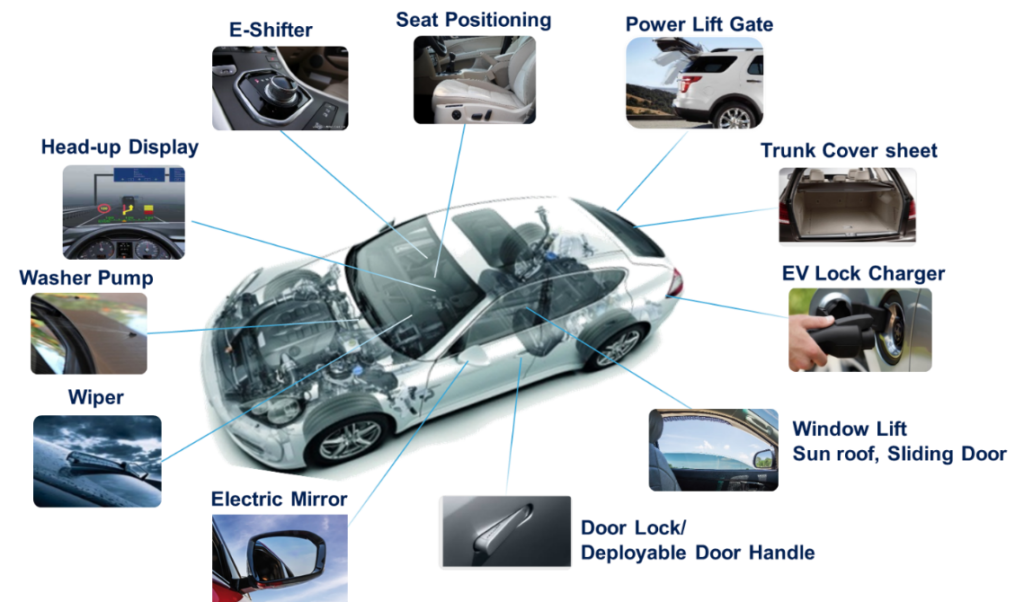

Body Domain

- The body domain contains functions embedded in a vehicle that are not related to the control of its dynamics.

- Wipers, lights, doors, windows, seats, cameras, and mirrors are controlled more and more by software-based systems that come under the Body Domain.

- It has to be noted that the body functions often involve many communications between each other and consequently have a complex distributed architecture, as systems of body domains are not confined to one area of the vehicle. Like Wipers are there in front of the vehicle, whereas parking cameras are there in the back of the camera.

Body Control Module Systems:

- External lighting

- Interior lighting

- Windshield wipers

- Central Locking system

- Seat Adjustment

- RF reception

- Immobilizer

- Remote Keyless Entry(RKE)

- Passive start and entry systems(PASE)

- Tire Pressure monitoring system

- Energy management.

Thus this system has low-cost sensor-actuator level networks, for example.

- Several functions can be associated with a door: lock/unlock control according to a signal transmitted by a wireless network, window control according to passenger or driver request, as well as mirror control and seat position control. One possible deployment of these functions could be that one main electronic control unit (ECU) supports the reception of the requests (lock/unlock, window up/down, seat up/down, etc.) while the controllers for the motors realize the requested actions on the physical device (mirror, window, seat) are supported by three other ECUs (Figure .). These four ECUs are connected to a LIN. As some requests concern several doors (e.g., the lock/unlock request), the main ECUs of each door are also connected, for example, on a low-speed CAN. Finally, to present the status of the doors to the driver (doors open/close, windows open/close), the information is transmitted by the main ECUs to the dashboard ECU via the CAN low-speed network.

Telematic and HMI

- Telematics in vehicles includes systems that support information exchanges between vehicles or between vehicles and road infrastructures.

- Telematics in vehicles includes systems that support information exchanges between vehicles or between vehicles and road infrastructures.

- Headunit

- GPS Navigation Systems

- Vehicle-to-Vehicle Communication

- Roadside assistance

- Emergency call(eCall)

- Consumer device Integration(Android Auto)

- HMI systems support, in a general sense the interaction between the driver and the passenger with numerous functions embedded in the car

- Their main functionalities are:

- presenting information about the status of the car (e.g., the vehicle speed, the oil level, the status of a door, the status of lights, etc.).

- Presenting the status of a multimedia device( current frequency for a radio device) or the result of a request( visualization of a map provided by a navigation system)

- Receiving requests for multimedia equipment(command for radio, navigation systems, etc).

Communication between a car and its environment (vehicle-to-vehicle [V2V] or vehicle-to-infrastructure [V2I]) will become more and more important in future years and will bring with it various services with strong added value. The future technologies in this domain begin with efficient voice recognition systems, line-of-sight operated switches, virtual keyboards, etc. but will evolve to include new systems that monitor the status of the vehicle and consequently manage the workload of the driver by avoiding, for example, the display of useless information.

- Digital Instrument Clusters.

- Heads UP Display

- Rear-Seat Entertainment

- Voice Operated Systems

- Haptic Technology

- In-Car Connected Payments

- Driver-Monitoring Systems

Conclusion

So, you can see that in a single vehicle how large number of electronic sub-systems are there and all these electronic sub-systems can be divided into above specified 5 domains. This blog must have given you good amount of understanding that what all electronic sub-systems are there in a vehicle and which electronic sub-system comes under which part of vehicle.

Now further to learn and grow, it is highly recommended to explore what kind of DIY projects then can make on their own for these domains of the vehicle.

DIY Projects for functional systems in car

Okay, so now we have gotten to know about the functional domain in the car, now let’s get into some practical projects and hands-on activity concentric to mimicking different automotive electronic sub-systems of different domains. As always, one of the first things that we would need to make automotive electronic sub-systems is a Microcontroller or Microprocessor. And to use the Microcontroller/Microprocessor, we will need a development board around it.

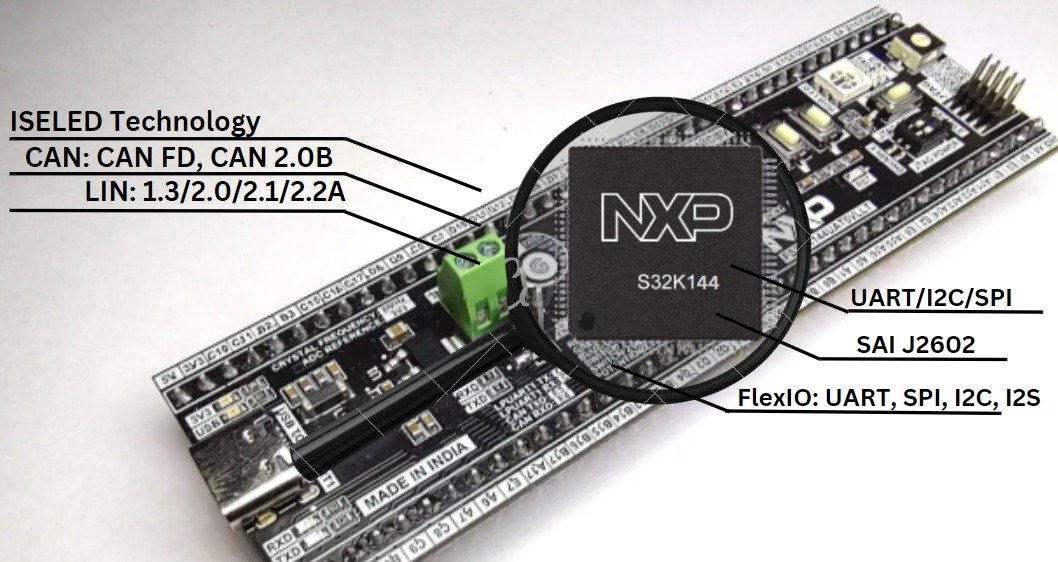

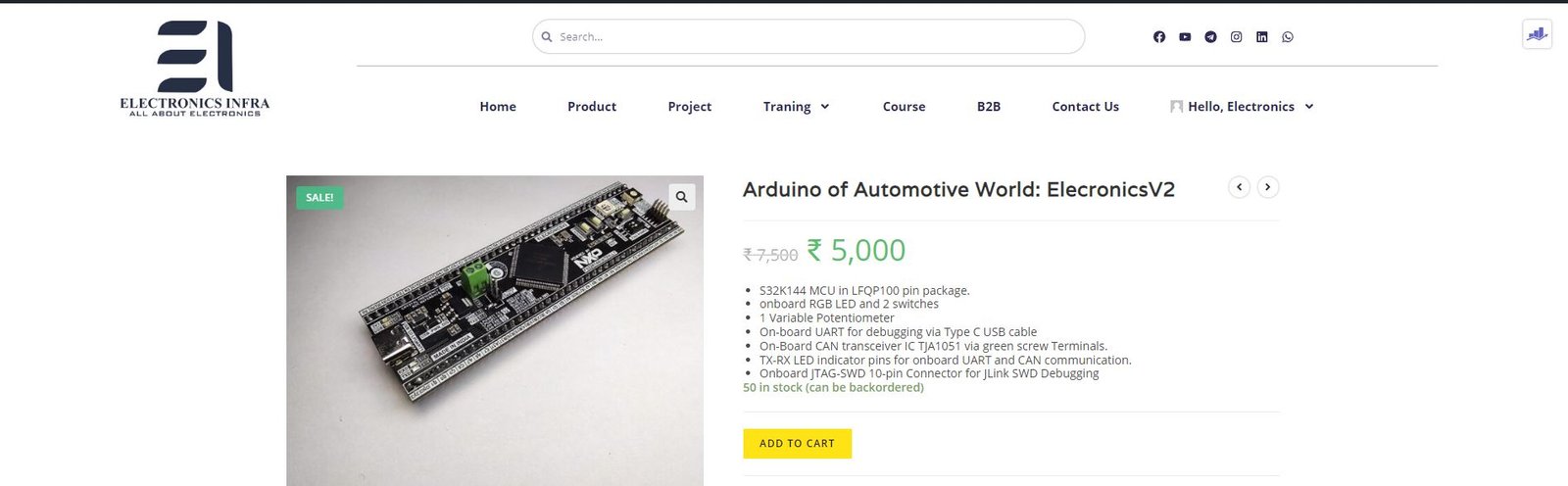

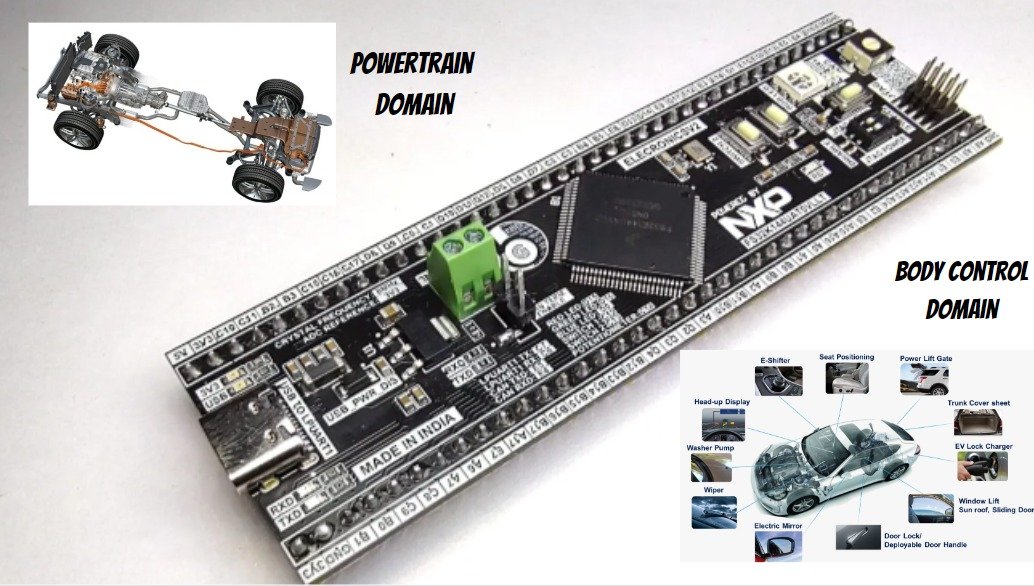

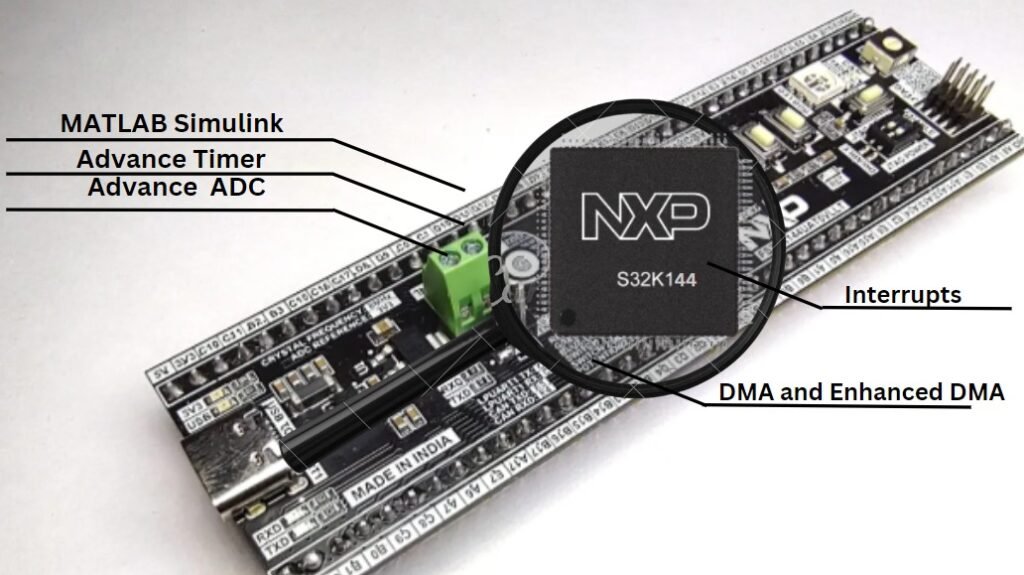

ElecronicsV2 is an Automotive Development board based on NXP Semiconductors S32K144 Microcontroller. Using this Development board, various electronic sub-systems related to Powertrain and Body Domain can be made.

ElecronicsV2 board is ideal for ECUs that are used in the Powertrain and Body domain. ECU is a Electronic Control Unit, which has a microcontroller/microprocessor central to it.

Powertrain Applications:

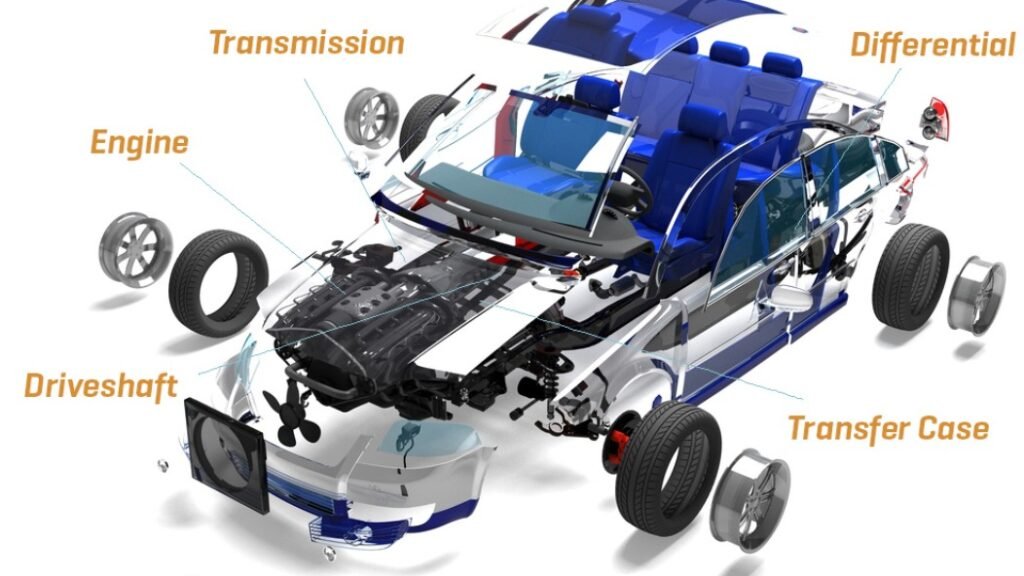

When it comes to understanding your vehicle, the powertrain stands out as the beating heart of the entire machine. In a vehicle, the powertrain comprises the main components that generate power and deliver that power to the road surface. The term “powertrain” encompasses a series of components working together to ensure your car moves efficiently and reliably.

This series of components in powertrain, consist of sensors like:

Powertrain Motor Driver’s for Induction, Permanent magnet synchronous motor (PMSM), Switched Reluctance motor (SRM) or Brushless Direct Current (BLDC) and Brushed Direct Current (BDC) motors. These motors are the ones which moves our vehicle ahead and put them into motion. E.G:

Powertrain Pressure Sensor to measure pressure of engine oil, pressure of atmosphere for fuel delivery and give important readings related to health of Engine which is used by various control system algorithms running in ECU’s of Powertrain domain.

Powertrain Temperature sensor for measuring temperature of engine coolant, Transmission and Engine Oil, boost and manifold air. These readings are very important to ensure the proper function of Powertrain systems, as over heating or extreme low temperature readings can cause unwanted incidents.

Powertrain Speed sensor for measuring rotation speed of engine shaft and vehicle speed. From these sensors, readings are given to Infotainment to show the speed of the vehicle to passsengers.

And other miscellaneous sensors like Knock sensor, fuel level sensor, Mass Air flow sensors, Engine Oil Condition sensors and etc.

ElecronicsV2 board has the support of MATLAB Simulink for developing motor control applications that fall under powertrain applications. All these sensors listed above can be interfaced with ElecronicsV2 board, by using advanced ADC and Timer peripherals present in S32K144 Microcontroller. It also features enhanced DMA and Interrupts for real-time and critical use cases in the powertrain domain.

Body Control Applications:

When it comes to providing comfort to passengers and having luxury in car. It’s the Body Control Domain sub-systems which come into picture.

Sensors like:

Solar and Ambient light sensors for car interiors.

Rain light humidity temperature sensor above the front mirror to ON the wipers automatically depending on weather conditions.

Stepper/Servo/DC motor and motor drivers for windows, wipers and seat

Optical sensor for auto-dimming rearview and side mirrors.

GEsture sensor to open the Truck by hand or leg

2.4 GHZ RF Transceiver IC’s for remote keyless entry(RKE) and passive entry passive start(PEPS) system.

ElecronicsV2 board supports ISELED technology. This technology is used for next-generation smart LED lighting systems mainly for automotive interior lightning. All the sensors/actuators/modules which are used in Body Control Domain can be connected to ElecronicsV2 using I2C, SPI, UART, ADC and PWM peripherals of S32K144 MCU

Using these peripheral various small nodes in the car can be connected easily to each other. Apart from that, it has support of variety of automotive networking protocols like CAN, LIN, and SAE J2602. S32K144 Microcontroller supports latest versions of CAN 2.0B and CAN FD.

These features make the ElecronicsV2 board ideal for the Body Control Domain. Various sensors and actuators concerning the Body Control Domain can be connected and are connected via the CAN-LIN network.